FOR IMMEDIATE RELEASE

MEDIA CONTACT

Lisa Winton, CEO, Winton Machine Company

770.831.1917 | sales@wintonmachine.com

Metro Atlanta October 18, 2018 – Winton Machine designs and manufactures tube fabrication machines for many applications in the HVAC/refrigeration, aerospace, automotive aftermarket, furniture, electronics and military industries. Winton manufactures over 100 different machines which use their proprietary software making automation and customized batches easy to program. With over 20 years solving customers’ problems in the USA and in countries across Europe, North and South America and Asia, Winton’s engineered solutions often become standard features and options for many of their machines.

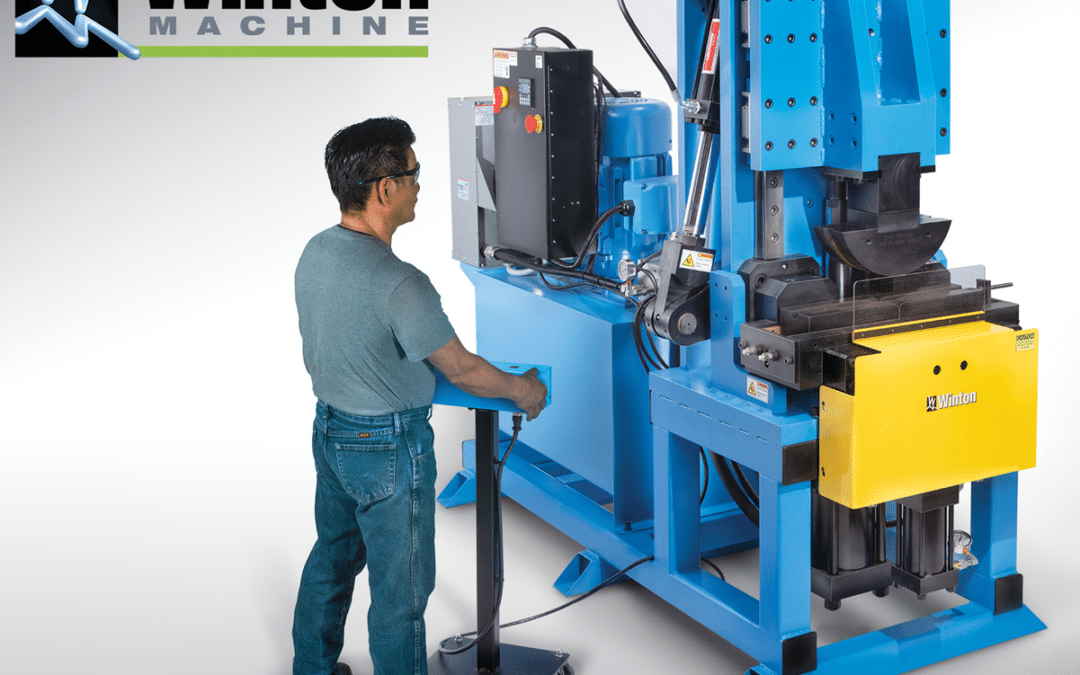

Some of our largest customers in the HVAC/refrigeration industry who need copper and aluminum tubular parts and subassemblies are successfully using the Winton OB23 Orbital Tube Bender and Tube Cutting Machine. OEM manufacturers producing commercial air handlers, beverage machines and refrigeration equipment are a few examples where the Orbital is saving money and improving efficiency.

The Orbital combines two or three machines into one allowing for tube cutoff, bending and end forming. It pulls the copper from a bulk spool, straightens it, bends it and drops off a completely severed part. This economical machine allows increased profitability through reduced cycle time and better use of labor resources.

“When we designed the Orbital, we focused on cost savings and efficiency,” said George Winton, P.E., Chief Engineer, Winton Machine Company. “We accomplished all of the design objectives by combining multiple operations or processes into one seamless system versus three separate ones which enables one operator to produce the necessary parts.”

Winton added, “By combining multiple operations into one, our customers experienced a lower cost of goods sold since the time to produce a fabricated tubular part was reduced. Safety and quality are improved because an operator does not have to handle the part between operations or handle the part during cutoff, bending or end forming.”

Winton Machine USA OB23 Orbital Tube Bender and Tube Cutting Machine combines tube cutoff bending and end forming.

The OB23 Orbital can be programmed by either directly entering in data from a 2D drawing into the PC interface or the user has the option to read in a STEP file direct from CAD. Either way, the machine is simple to program. The Windows interface operating system allows an operator to edit programs, view 3D models, run the machine as well as store programs for future use. The OB23 utilizes on-board diagnostics, and user-friendly help screens help navigate bender functions ensuring that the machine stays operational.

Like all the Winton machines, the Orbital was designed with safety in mind. The Safety Laser Scanner, E-stops, and Guard Door Interlocks all come standard on the machine to safeguard the operator. The Laser Scanner monitors the perimeter for unintended objects for the operator’s protection.

Learn more about the OB23 Orbital Bender and its features:

Video: Orbital CNC Tube Bender with an End Former. Cuts, Bends and End Forms Tubing in One Machine

OB23 Orbital CNC Tube Bender Feed, Cut, & Bend One Operation from Winton Machine on Vimeo.

OB23 Orbital CNC Tube Bender and Tube Cutting Machine ›

OB23 CNC Orbital Tube Bending System with Integrated Tube End Former ›

About Winton Machine

Winton Machine manufactures over 100 different machines which use their proprietary software. The company continues to expand its line of tube and coax fabrication equipment. Engineered solutions often become standard features on many of the machines. Winton has over 500 customers in the United States and in countries across Europe, South America and Asia. Winton Machine partners with agents in Russia, Canada, Mexico, Colombia, Israel, India, Saudi Arabia, Dubai, China, Egypt, Poland, Japan and France.

A noteworthy honor for Winton Machine was representing the State of Georgia at the 2018 White House “Made in America Product Showcase” event. They were recently awarded two Gwinnett Chamber of Commerce 2018 Pinnacle Awards for Overall Small Business and Small Business: 25+ Employees.

Winton specializes in providing engineered solutions in major industries such as HVAC/Refrigeration, Aerospace, Automotive Aftermarket, Furniture, Electronics and Military. Winton is privileged to serve top companies and organizations in the U.S. and around the world. Learn more at www.wintonmachine.com