Tube Fabrication Machines

CNC Orbital Tube Benders

Rotary Draw Tube Benders

Serpentine Tube Benders

We offer a series of options for serpentine tube bending. Perfect for the refrigeration and heat transfer markets, where copper tubing is used.

CNC Roll Benders

Compression Tube Benders

Winton offers a line of high speed vertical compresson benders. These machines are designed to get the maximum number of parts off the floor per day.

CNC Tube Cutting Machines

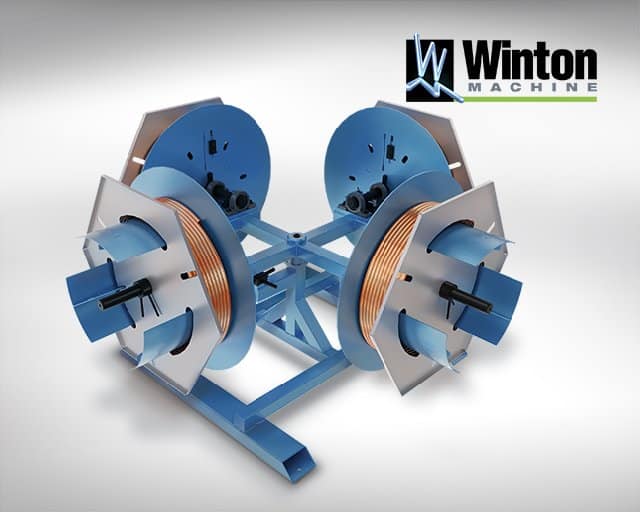

Rotary Position Uncoilers – Tube Payoffs

Winton uncoilers feed copper and aluminum off a bulk spool into a Straight Tube Cutoff or other Tube Fabrication machines. The addition of a payoff to your operation can save you material and labor costs.

End Formers

Fabrication Systems – High Speed

Our fully automated tube fabrication systems are designed for high-volume production. We can take your existing operation and combine several steps into a single fabrication operation.

Tube Fabrication Systems

Winton Machine creates full service tube fabrications systems to improve your operation’s efficiency and quality.

Tube Straighteners

Hand Benders

Digital Protractors

Crimping & Swaging Machines

We have experience building tube benders, cutoff machines, end formers, measuring devices, and transfer machines.

High volume production is the name of the game when it comes to bending copper for refrigeration applications. This is where Winton has been successful providing equipment to cut, bend, and end form tubing to OEMs all around the world.

The spectrum of fabrication equipment has ranged from simple CNC tube benders to high volume transfer machines used to impart several operations on a single work piece in just a few seconds.

One of our goals is to engineer a solution that best fits the needs of our customers. This may be fullfilled utilizing one of Winton’s standard products, modifying our equipment, or a complete engineered solution. Whatever the need, Winton is dedicated to figuring out the best and most economical solution to be sure that our customers benefit from their return on investment.

Give us a call today at 888-321-1499 or fill out our contact us form online. We look forward to helping your bottom line.

Contact Winton Machine

About the Machines We Build

Our factory automation solutions are used to help manufacture the NASA Mars Exploration Rover, Mars 2020, Raytheon Iron Dome Weapon System used to help protect over 8 million people in Israel to mass production of refrigerators built on General Electric assembly lines.

Winton Machine designs and manufacturers all our machinery onsite in Suwanee, Georgia – just northeast of Atlanta. We manufacture over 100 different machines and have also developed our own proprietary software that is used exclusively on Winton Machine products. The company continues to expand our core line of tube and coax fabrication equipment by adding customer-requested features and creating engineered solutions for the specific manufacturing needs of customers.