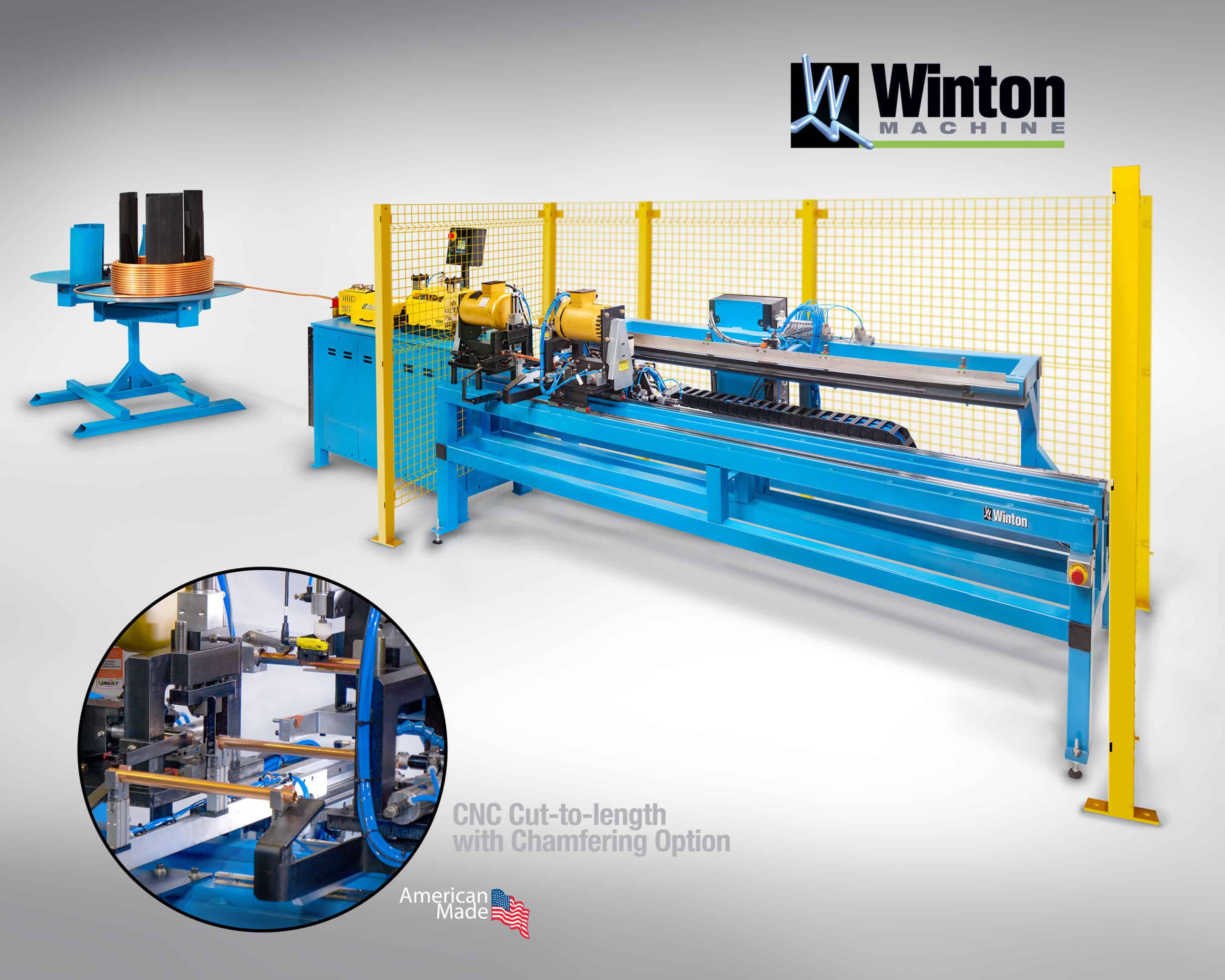

Chamfering Tube Cutting System

Chamfering Attachment Model #: 21456-5005

This chamfering attachment can work both ends of a tube simultaneously while the straight tube cutting machine is feeding the chamfering attachment. If you are also bending tubes at your production facility by deburring the ID of the tube, you can improve your mandrel tube bending operation.

Your safety team can help quantify your purchase as not only is it safer for your employees to handle deburred tubes, but the Winton chamfering attachment also performs the task automatically so there are fewer opportunities for accidents.

This tube cut-off fabrication system is ideal for industries such as HVAC, Refrigeration,

automotive, lighting, lawn and garden, aerospace. and more.

Let us know how we can further automate your tube fabrication processes.

Learn About Adding a Chamfering Attachment to a Straight Tube Cutoff Machine

Product Video & Details

Specifications

Tube Diameter Range | 0.250 to 1.125 |

OD chamfer tooling | Replaceable carbide inserts |

Power requirements | 208/3/60, 5K Watts, consult factory for other voltages |

Footprint | 60” deep x 120” wide, consult factory for shorter systems |

Chip blow off nozzles | Included |

Cutter lubrication, automatic | Included |

Dynamic chamfer head positioning | Servo controlled, automatically adjusted, Included |

Box guarding | Included on three sides of the system |

E stop | One (1) included on the front side of the chamfering machine |

Tube transfer device | Automatic via walking beam system |

Tube materials | Copper and aluminum, consult factory for other materials |

Compressed air | 80 psi minimum shop air required, 0.5 SCFM required |

Safety

Safety is a mission-critical part of the continuous improvement culture at Winton Machine Company. Our machines are designed with advanced safety features and are regularly inspected to ensure they meet the highest safety standards. We also provide comprehensive training and resources to ensure your operators are fully equipped to use our machines safely and effectively. As machine safety options evolve, Winton Machine evaluates new safety trends to integrate proven and well-vetted design upgrades in all our machines which are engineered, manufactured and serviced here in the United States.