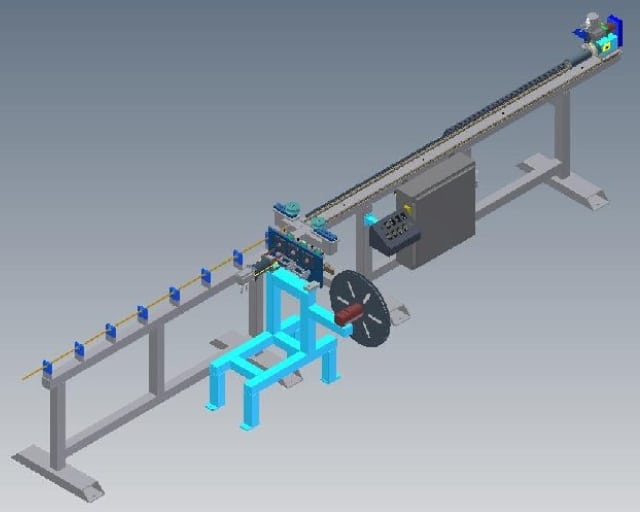

SFW30 Spine Fin Wrapper

Model #: 21431

Manufacture Short Lengths (<16 feet) of Spine Fin Wrapped Tubing

Winton now offers a system to manufacture short lengths (<16 feet) of spine fin wrapped tubing. Excellent for heat transfer efficiency, the system can produce a spine fin wrapped tube of various lengths. The system can accommodate a range of tube diameters from 3/16″ to 1-1/8″. The three axis servo driven system allows a user to program the pitch and length of the wrapped tubing…all on the fly. With the base of the spine fins in firm contact with the tubing, the effective surface area of the tube is greatly increased causing the wrapped tubing to dissipate more heat given a fixed length of tubing. The system can accommodate a range of materials. Contact Winton today to discuses your spine fin needs.

Product Video & Details

Customers using Internet Explorer may have difficulty viewing the online training videos.

We suggest using Chrome, Safari, Microsoft Edge, or another modern internet browser to view our videos. To find out more about the system requirements to view our training videos, and to see if your device meets them, click here.

Safety

Specs & Equipment

- Microprocessor controlled with touch screen for the user interface

- Programmable wrapping pitch & linear processing speed

- Programmable length of spine fin wrapped tubing

- System can accommodate a tolerance of ±.010″ on the tubing OD

- Interchangeable tooling

- 15 minute change over time from one diameter to another

- Fast load and unload from part to part

- 3 axis AC servo driven system

- 220/60/1 service req’d

- 80 psi shop air req’d

- All guards included