Pulling The Wrinkles Out of Copper Tube

Looking better with less wrinkles

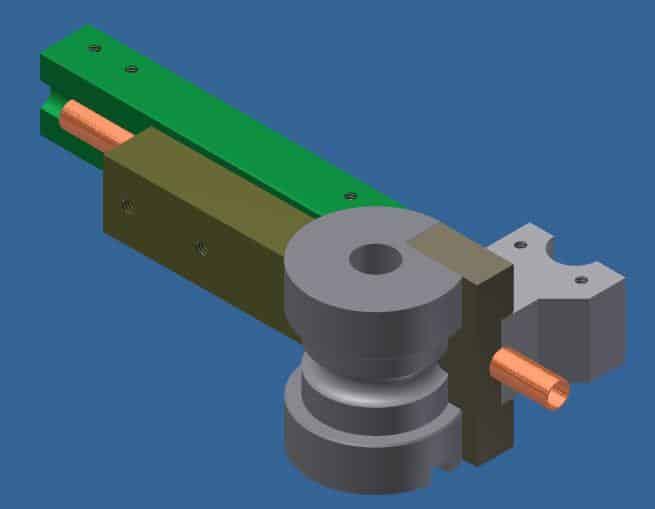

The vast majority of copper tube bending never comes close to producing wrinkles on the inside of a bend. However, the design of some bent tubular parts is prone to wrinkles. If the bend radius is small enough and/or the wall thickness is thin enough, a wiper die may come into play. Nevertheless, when it comes to tight radius/thin wall bending, a wiper die is used to prevent wrinkles from forming on the inside of a bend. The way in which a wipe die does this is most interesting.

How a Wrinkle Forms

Simply put, as a tube transitions from a straight section to a bent section, it undergoes compressive stresses on the inside of the bend. When these compressive stresses exceed a certain limit, the inside wall may buckle protruding away from the wiper die and towards the outside wall of the tube (path of least resistance). A wiper die, in part, is used to help offset or limit these compressive stresses in an attempt to make a wrinkle free bend. So the question then becomes how exactly does a wiper die limit the compressive stresses when attempting a tight radius bend.

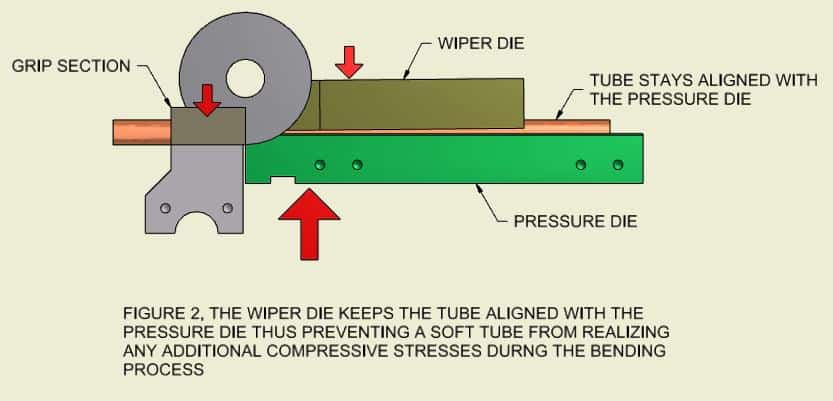

Firstly, in a similar fashion to how pinch tooling works to improve the outside appearance of a bent tube, a wiper die helps support a tube as the pressure die first makes contact with the tube. Secondly, once the pressure die is in contact with the tube, the wiper die continues to apply a force on the tube while the bending process is underway. At both times during a bending cycle, the wiper die is critical to supporting the inside of the tube.

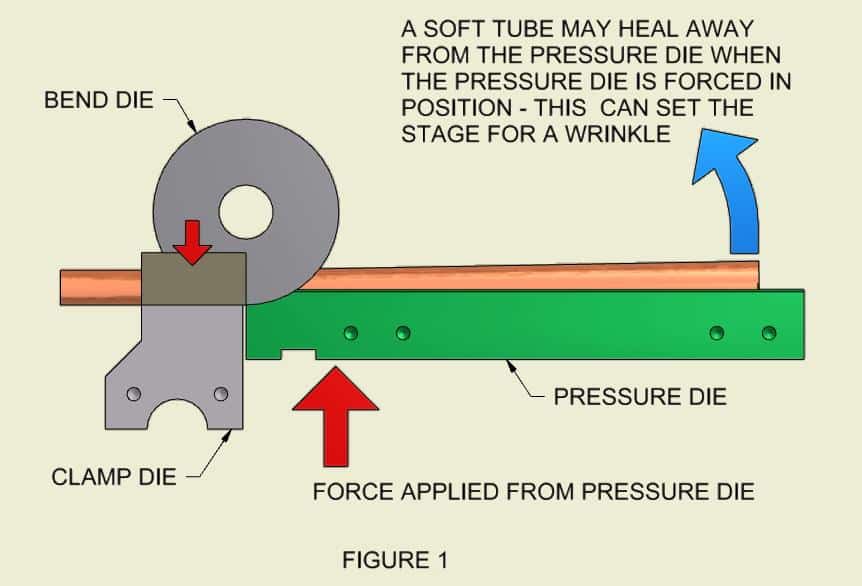

Right before the tube experiences a bending torque, the wiper die goes to work preventing the tube from separating from the pressure die. Figure 1 depicts a tube separating for the pressure die without the aid of a wiper die. This can be most obvious when bending a soft material such as 3003 aluminum or copper without a wiper die. The conditions usually arises when the when the centerline bend radius approached the tube’s outside diameter (1D bend).

If the tube significantly separates from the pressure die prior to or during the bending motion, the tube itself can experience an additional compressive stress component in the area surrounding the bend tangent. Thus, one goal of a wiper die is to insure the tube stays aligned (parallel) to the pressure die as the tube itself is being drawn into the bending process.

The Bridge Support Concept

If you have a grip section in a bend die opposing the pressure die, and you have the wiper die on the other side of bend tangent also opposing the pressure die, then the pressure die is supported on both sides; see Figure 2.

If you were to remove the wiper die from the bending process, a soft copper tube may have a tendency to separate from the pressure die prior to and during bending; see Figure 1. Thus, in part, a wiper die is used to impart force on a tube prior to and during the bending motion. This force counteracts the compressive forces within the tube induced by the bending process itself.

George Winton, P.E. designs and builds CNC tube fabrication equipment for Winton Machine in Suwanee, GA. He can be reached at gwinton@wintonmachine.com or 888.321.1499.

About the Machines We Build

All of our semi-rigid coax and tube fabrication machines at Winton are designed, manufactured, and tested in-house. We have a large line of standard products as well as the ability to engineer the best solution for our customer’s needs. Our experienced sales staff makes sure that our customers can justify their capital equipment investment by offering a solution that is exactly what they need in order to manufacture their parts. Please contact us today to discuss your project.