Embracing the Wrinkle

How turning the tables on an unwanted wrinkle can be profitable.

There has been a lot of time and money spent on removing unwanted wrinkles. I’m not talking about the botox industry. I’m talking about those unwanted ones that have a tendency of appearing on the inside of a bent tube. Maybe you have caught yourself saying: “If I could just get rid of the wrinkles, I could ship these parts”. Or “If the customer would just increase the wall thickness, production would be run a lot smoother”. It goes on and on.

The quest to eliminate the wrinkles continues to generate cash flow all over the world… all in an effort to accomplish one or more of the following:

• Improve the flow of a liquid or gas thru the tube

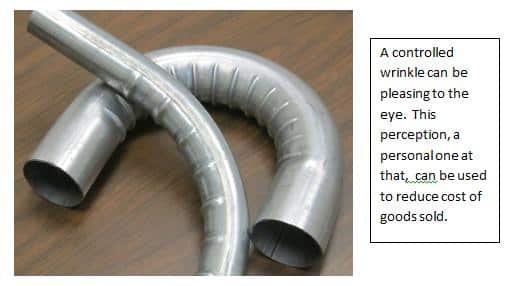

• Improve the cosmetic look of the tube

• Pacify the perception of the customer regardless of the fact that the tube may not be seen by the end user and/or the presence of a wrinkle may not have a significant effect on the flow inside the tube

In a large number of cases, the presence of wrinkles is not good. For example, a light fixture hanging in a dining room that sported random wrinkles could easily conger up the impression of low quality. Or imagine a very tight bend radius used on a car’s exhaust pipe that has wrinkles. The additional back pressure caused by the wrinkles could easily equate to fewer miles per gallon.

tens by any significant amount, then the fluid that is intended to pass thru the tube will experience more of a restriction; see Figure 1. It is just like a garden hose; pinch the hose enough and the flow will stop.

If you can’t Beat’em – Join’em

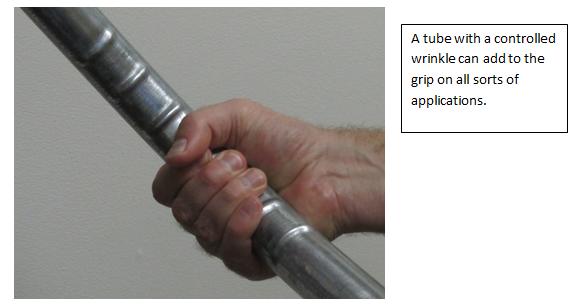

You may have an option here. Consider sharing with your customer as to the benefits of a controlled wrinkle. That’s right. Embrace the wrinkle! Get rid of the wiper die (and maybe the mandrel but that is a different story).

If you think a controlled wrinkle may be for you, consult your bend tooling provider. They should be able to look at your application and make suggestions about what you can expect. Nevertheless, at the end of the day if you can save on your COGS and pass some of the saving onto your customer, the implementation of a controlled may be a win-win situation.

Controlling the Wrinkle

The feature to control a wrinkle is machined into the bend die. How the bend die is machine takes into account, at a minimum, the tube OD, wall thickness, tube material, and bend radius.

Once these factors are established, the details on how to impart the controlled wrinkle features into the bend die start to become evident.

George Winton, P.E. designs and builds CNC tube fabrication equipment for Winton Machine in Suwanee, GA. He can be reached at gwinton@wintonmachine.com or 888.321.1499.

About the Machines We Build

All of our semi-rigid coax and tube fabrication machines at Winton are designed, manufactured, and tested in-house. We have a large line of standard products as well as the ability to engineer the best solution for our customer’s needs. Our experienced sales staff makes sure that our customers can justify their capital equipment investment by offering a solution that is exactly what they need in order to manufacture their parts. Please contact us today to discuss your project.