When There’s No Straight in the Mix

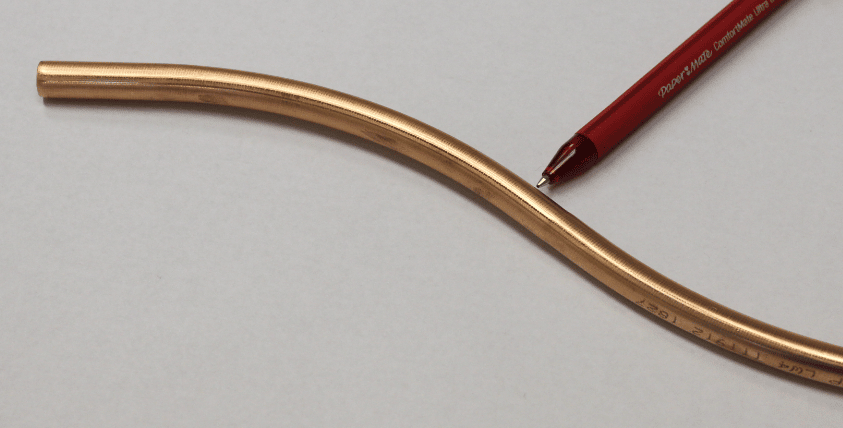

You’ve heard it for years. Everyone knows the rule. But then a request comes in for a part with two bends back to back with no straight segment between the bends. The “no straight” part has been internally frowned upon for years because it most often takes special tooling on a rotary draw bender and, quite frankly, most folks don’t want to pony up for special tooling. So what do you do? You try talking your customer into adding a small straight section, but no luck. They need the part as is and you want the business. What now?

Then it hits you like a rock. You have been thinking for years in the mind set of rotary draw bending. It has always served you well. But now you immediately start thinking about how a rotary compression process could solve the “no straight” problem. This is a great idea because with the right tooling / setup, the problem can be solved. Making a back to back bend profile via a rotary draw process can get expensive, however, an understanding of the compression process will add a new tool to your shed.

Using Rotary Compression

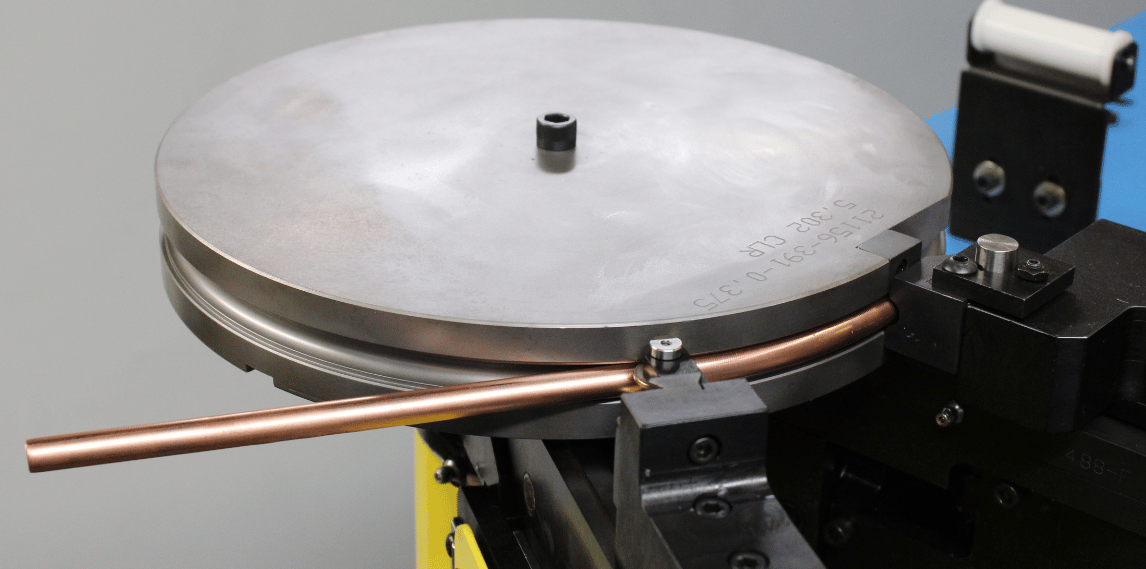

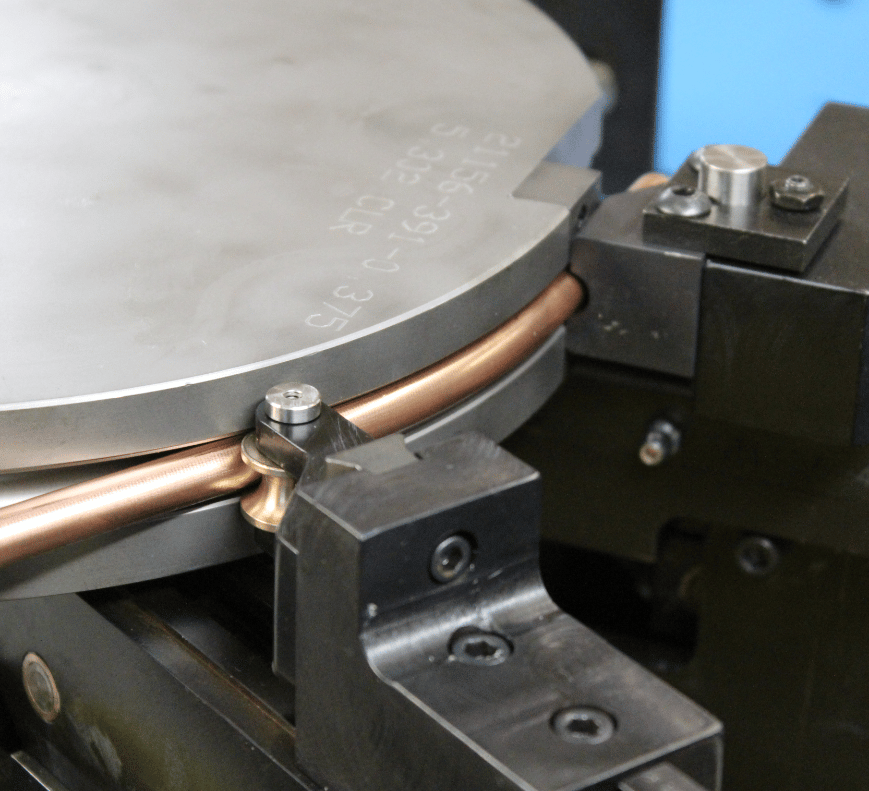

The compression bending process doesn’t allow the tube to draw in during the bending process. Rather it clamps the tube on one side (holding it firm) and then allows for a wipe shoe to sweep around a bend die. In this case, the wipe shoe serves to wipe or sweep the tube around the bend die while the clamp die holds the tube in a static position. A wipe roller can be used to reduce the friction as the tube is being wiped around the bend die.

One of the main advantages of the wipe bending process is it can form bends with no straight between the bends. This bending technique can apply to NC and CNC type benders. It is all a matter of tooling up and having your software match up to the forming process.

In general, a wipe roller should spin as is wipes the tube around the bend die. A free spinning wipe roller prevents scratching or galling on the tube. Remember, the bend die in a wipe process is not rotating. Therefore, as the wipe roller pushes the tube around the bend die, the overall friction of the bending process is reduced because the wipe roller rolls and doesn’t drag. Therefore, let it roll!

Quite often the tooling used on a wipe bender can also be used on a draw type bender. The clamp dies and bend dies are often interchangeable. The wipe roller doesn’t have to be a roller. In some applications it can be a rectangular plastic shoe, the same type of shoe used in a draw bending process. The most flexible CNC tube bender is one that allows for draw bending and wipe bending all within the same part.

George Winton, P.E. designs and builds CNC tube fabrication equipment for Winton Machine in Suwanee, GA. He can be reached at gwinton@wintonmachine.com or 888.321.1499.

About the Machines We Build

All of our semi-rigid coax and tube fabrication machines at Winton are designed, manufactured, and tested in-house. We have a large line of standard products as well as the ability to engineer the best solution for our customer’s needs. Our experienced sales staff makes sure that our customers can justify their capital equipment investment by offering a solution that is exactly what they need in order to manufacture their parts. Please contact us today to discuss your project.