When a Cylinder Won’t Move – Troubleshooting

The basics of troubleshooting a hydraulic or pneumatic cylinder on an industrial machine

It doesn’t matter what type of machine you have, chances are the control circuit for a hydraulic or pneumatic cylinder are very similar. This is true for tube benders, tube cutter, tube end formers, and more. Getting the cylinder to move reliability is the job of the machine tool builder. Keeping it moving is often the job of the maintenance department. Having an understanding of just how to trouble shoot a non-preforming cylinder can be useful knowledge across all types of tube fabrication equipment.

For the most part when you are faced with a cylinder that is not moving, the first question should be is it mechanical or is it electrical. The answer to this question will tell you what side of the fence to look on to find the cause of the problem.

Mechanical

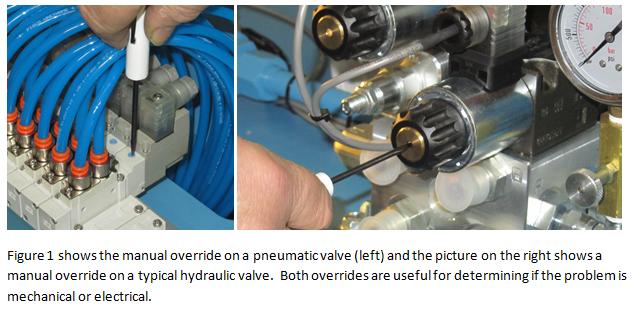

Most pneumatic and hydraulic valves have mechanical overrides. The simplest thing to do is actuate the mechanical override. Figure 1 shows the position of the mechanical overrides on two common valves. Activating the override can demonstrate if the problem is mechanical or not. If you press the override and the cylinder moves freely, you need to start looking for an electrical solution.

Electrical

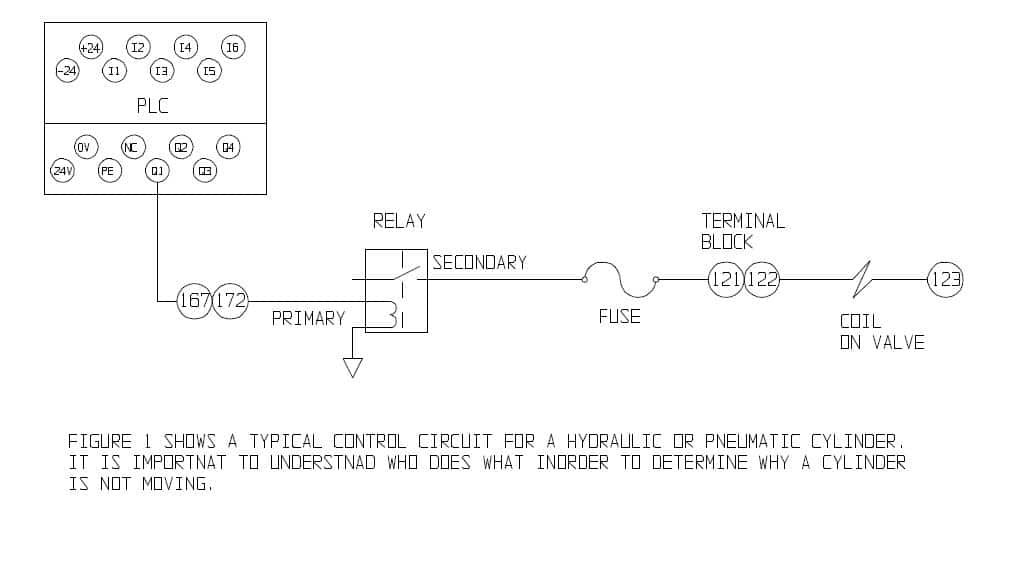

In most industrial machine tools, a cylinder moves when a PLC tells it to move. A typical chain of command is shown in Figure 2. The firing order is as follows:

• An output on a PLC goes active

• A relay then goes active as a result of the PLC output going active

• A DIN connector on a valve then goes active as a result of the relay going active

• The cylinder then moves as a result of power being applied to a valve’s DIN connector

With any luck, your machine has LEDs on the relay and DIN connector. This is most helpful when trouble shooting. With this in mind, here is a overview of what makes a cylinder move electrically:

When you know the cylinder should be moving, verify:

- The voltage on the output of the PLC is at the proper level. If it is a DC circuit, the voltage level may be active high or active low depending on how the circuit is designed. Also, the PLC may have a LED dedicated for that output. This is good. This will tell you when the PLC thinks the output should be active.

- With the proper voltage on the output of the PLC, look at the LED on the relay. Is it illuminated? If the LED is not illuminated, verify the voltage on the primary side of the relay. Even with the LED on the relay illuminated, verify the voltage level on the secondary side of the relay is active.

- If the relay looks to be in fine order, set your sights on the DIN connector mounted to the valve.

- Is the LED on the DIN connector illuminated? If there is no LED, verify the voltage inside the DIN connector. If the LED on the DIN connector is illuminated, you may have a faulty coil on the valve itself.

- Another approach is to first take a look at all the LEDs and see who is not active. Then, start your focus based on who is active and who is not active.

Not all control circuits make use of a relay to control a cylinder. Some valves draw so little current that a control relay is not necessary. However, it is common to find a fuse in the circuit protecting the coil on the valve. Making sure the fuse itself is not blown is always a good idea.

George Winton, P.E. designs and builds CNC tube fabrication equipment for Winton Machine in Suwanee, GA. He can be reached at gwinton@wintonmachine.com or 888.321.1499.

About the Machines We Build

All of our semi-rigid coax and tube fabrication machines at Winton are designed, manufactured, and tested in-house. We have a large line of standard products as well as the ability to engineer the best solution for our customer’s needs. Our experienced sales staff makes sure that our customers can justify their capital equipment investment by offering a solution that is exactly what they need in order to manufacture their parts. Please contact us today to discuss your project.