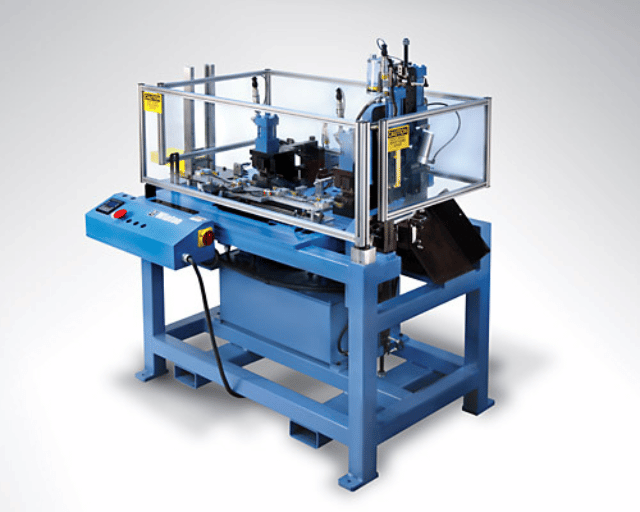

Programmable Transfer Machine For High Speed Tube Fabrication

Model #: 21373

Automatic Transfer Machine for High Volume Tube Fabrication

This 4 station transfer machine shown drops 1 part every 6 seconds. It doesn’t matter if there are 1 or 2 bends, the part production time is 6 seconds. The transfer machine shown is setup to flare both ends and then put 2 bends in the part. The benefits of this setup include minimal process time, significant reduced labor costs, and consistent fabricated parts.

Product Video & Details

Customers using Internet Explorer may have difficulty viewing the online training videos.

We suggest using Chrome, Safari, Microsoft Edge, or another modern internet browser to view our videos. To find out more about the system requirements to view our training videos, and to see if your device meets them, click here.

Safety

More Information

Retooling

The machine can be quickly retooled to bead 1 end, swage the other, and make only 1 bend. Numerous modular configurations are available.

Winton designs, builds, and delivers transfer machines for high speed tube fabrication. Bending, punching, end forming, assembly, and more are configurable on standard transfer platforms. Making use of standard forming modules, a typical 4 bend part can drop complete once every 5 to 6 seconds. Contact Winton to discuss your application today.

Specs & Equipment

- Programmable stations – allows user to make a family of different parts with minimal change over time

- Capacity: 25mm OD tube

- Functions: Tube bending & tube end forming

- Maximum number of stations: 4

- Typical cycle time (2 flares + 2 bends): 6 seconds per part

- Power: 240/480 VAC 3 phase

- 80 PSI shop air required

- Station design: modular design

- Controller: PLC

- All guards included

- Auto load and unload – standard

- Hopper loader – optiona