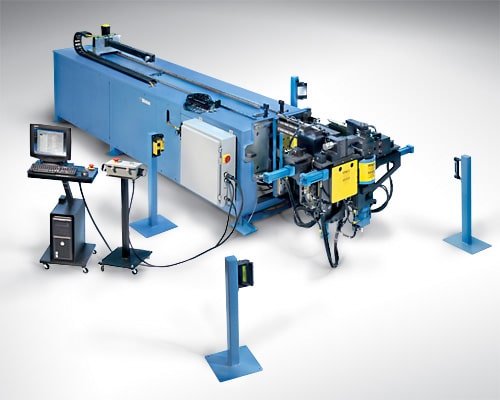

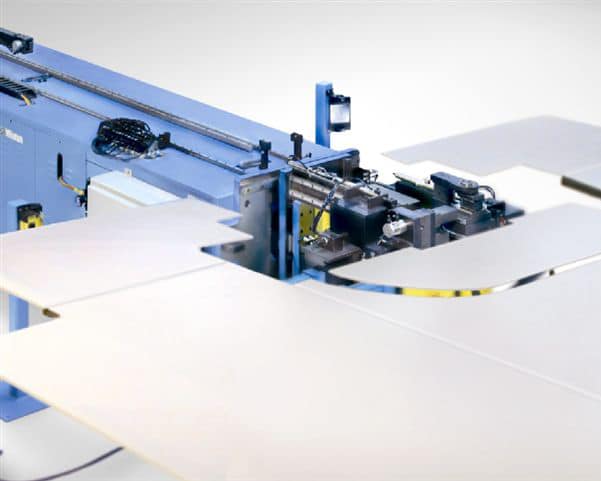

CB50 CNC Tube Bender – CW/CCW Extrusion Bender

Model #: 21350

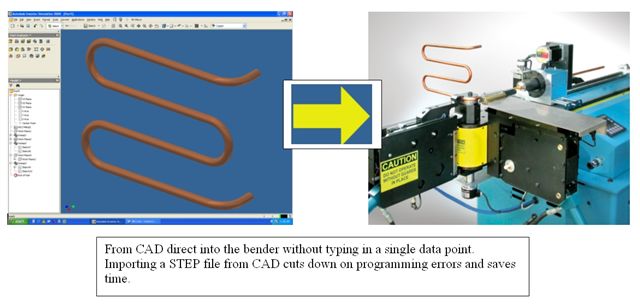

Controlled using a Windows-based interface, an optional STEP file converter will allow a user to import CAD model of a bent tube directly into the tube bender thus eliminating the need to manually enter LRA or XYZ data from a drawing. That means the latest bend data is imported directly from engineering into the tube bender. The benefits are minimal process time, significant reduced labor costs, and consistent fabricated parts.

Product Video & Details

Customers using Internet Explorer may have difficulty viewing the online training videos.

We suggest using Chrome, Safari, Microsoft Edge, or another modern internet browser to view our videos. To find out more about the system requirements to view our training videos, and to see if your device meets them, click here.

Safety

Features

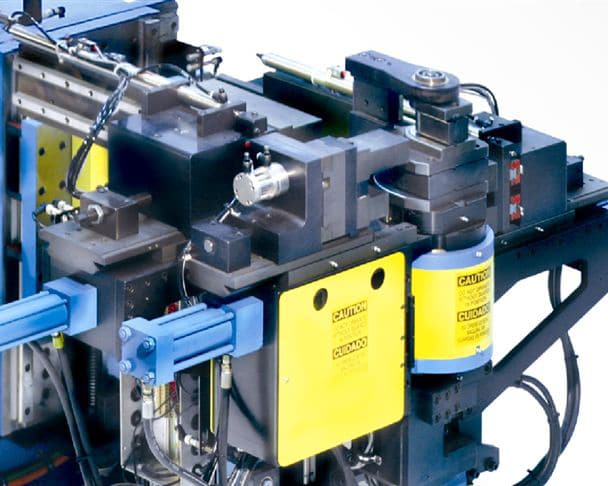

- 4 axis CNC tube bender for extrusions

- Windows-based interface

- Electric XY servo head shifter

- Right and left hand pressure stages

- Independent die boss – returns independently from swing arm

- Electric L servo used to advance material into the bend zone

- Hydraulic bend head – servo controlled

- Leading edge part detector – clocks the leading edge of a part

- Dual stack split-die actuator (shown) – optional

- STEP file converter used to import CAD files directly into bender – optional

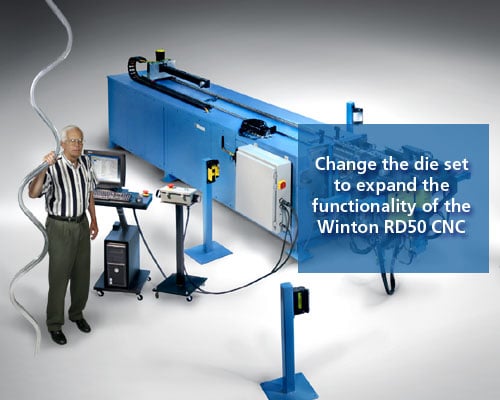

- Programmable tool library for efficient part programming

- Programmable material library for accurate springback gauging

- Programmable clamp and pressure dies – optional

- Mandrel extractor for quality tube bending (optional)

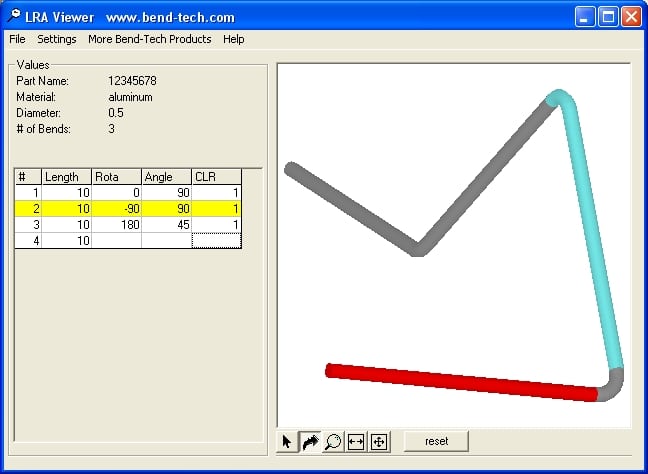

- 3D Model Viewer for LRA Data Verification – Optional

Inquire About This Product