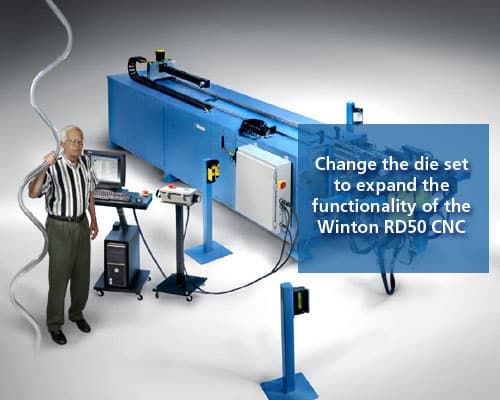

RD50 CNC Mandrel Tube Bender – Bends CW & CCW

Model #: 21350

Winton’s RD50 CNC tube bender is designed to make consecutive CW and/or CCW bends in a single work piece. An XY servo controlled head shifter positions the bend head in the correct orientation with respect to the material being bent. Therefore, the material being bent only moves in a horizontal plane towards the bend tooling and never up or down. This is important when bending extrusions.

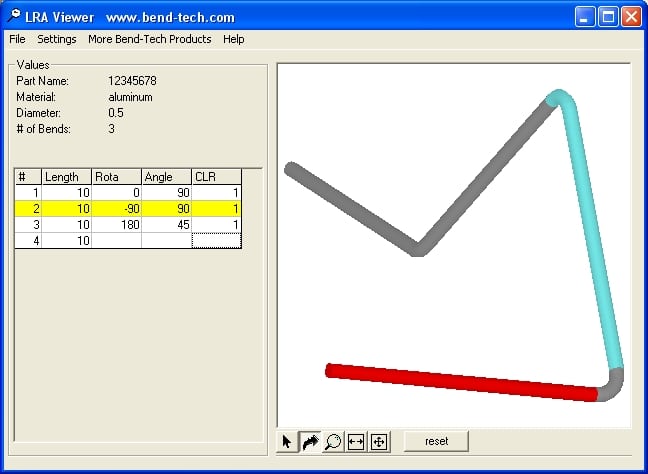

Controlled using a Windows-based interface, an optional STEP file converter will allow a user to import CAD model of a bent tube directly into the tube bender thus eliminating the need to manually enter LRA or XYZ data from a drawing. That means the latest bend data is imported directly from engineering into the tube bender. The benefits are minimal process time, significant reduced labor costs, and consistent fabricated parts.

Details

Safety

Safety is a mission-critical part of the continuous improvement culture at Winton Machine Company. Our machines are designed with advanced safety features and are regularly inspected to ensure they meet the highest safety standards. We also provide comprehensive training and resources to ensure your operators are fully equipped to use our machines safely and effectively. As machine safety options evolve, Winton Machine evaluates new safety trends to integrate proven and well-vetted design upgrades in all our machines which are engineered, manufactured and serviced here in the United States.

Features

- Model: CB50 CNC tube bender

- Capacity: 50mm OD tubing

- 4 axis servo controlled

- Optional R axis available (plane rotation)

- End chuch or hitch feeding available

- Leading edge part detector use clock part in bender

- Both CW and CCW tube bending

- Programmable post bent material support (consult factory,optional)

- Optional mandrel extractor

- Optional double stack tooling

- Optional split die actuator

- 3D Model Viewer for LRA Data Verification – Optional

Inquire About This Product