How to Process Coax Cable

Coax cable is a common means to transport high frequency signals in microwave communication systems. Coax cable can be found in commercial and military applications all over the world. Everything from cell phone towers to ship-to-ship satellite communication systems makes use of coax cable. Two common types of coax are semi-rigid coax cable and flexible coax cable. Cutting, stripping the ends, and bending coax are discussed below for both types of cable.

Cutting

Cutting Semi-Rigid Coax with a Saw

Semi-rigid coax cable often comes in straight lengths. Cutting semi-rigid usually involves a saw-type cut. A saw-type cut is preferred because the next step in processing the coax involves dressing the ends for fittings. If the ends are not cut square and/or have too much burr on the outside diameter, the coax stripping machine may not accept the end of the semi-rigid cable for processing.

A thin high-speed saw will cut thru the semi-rigid cable with little trouble. The outer jacket of a typical piece of coax is copper or aluminum with a plastic insulator surrounding the center conductor. With the right number of teeth on the saw, production can proceed as long as the saw blade keeps a sharp edge. As the blade dulls the burr on the outside diameter tends to increase.

The quality of cut is not the only QC feature to be concerned with. The repeatability of the cut length is most important. If the cut length varies too much, the VSWR will also vary. Selecting a cutting process that produces a square cut while at the same time cuts consistent lengths is most desirable.

Cutting Flexible Coax with a Saw System

Flexible coax cable is becoming more prevalent in commercial systems. Being flexible, the application that the flexible cable is used in may determine if the cable gets bent by hand or by CNC machine. Nevertheless, flexible cable, unlike semi-rigid cable, comes on a spool. Getting it from the spool, metered out and cut to precision lengths requires a cutting system that first straightens the cable. Once straightened, a saw type cut can be made.

The same saw blade that is used to cut semi-rigid coax can be used to cut flexible coax. Care must be taken to ensure that both sides of the cable are secured during the cutting process. Lack of support during the cutting process can lead to poor cutting results

Stripping

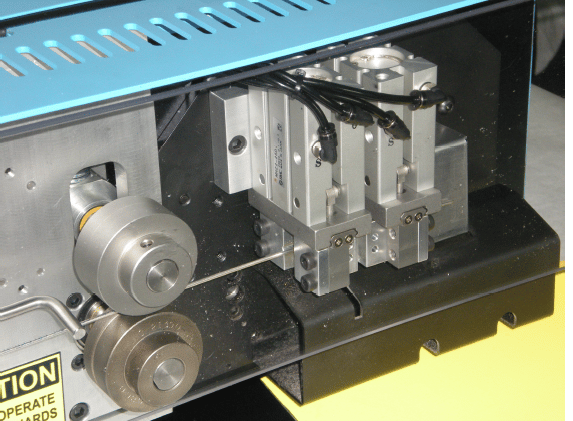

Once the cut lengths come off the saw with nice square ends, the ends of the cable can now be dressed for a connector. Dressing the ends may involve multi-step cuts in each end. One of the most important quality features of dressing the ends of a cable involve removing the outer jacket and insulator without nicking the inner conductor.

Nicking the inner conductor can lead to scrap parts. Therefore, choosing a stripping machine that is very repeatable regarding cut depth and stripped length is most important for proper signal transmission.

Bending

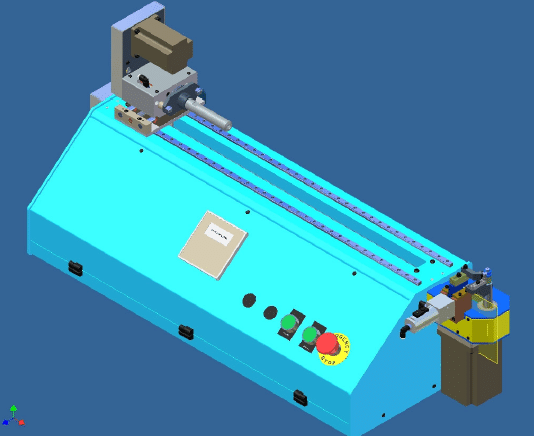

Consistent products shipped require consistent components. Thus the need to bend coax cable consistently. Consistent bending starts with a good set of bend tools. Bending tooling for coax cable involves a bend spool, clamp die, wipe roller. For CNC bending, a collet will be necessary. Bending coax by hand can yield the same results as bending via a CNC coax bender. The difference being that when bending by hand, the operator must remain focused in order to avoid quality problems down stream.

When choosing a center line bend radius, first review the literature from the manufacture of the coax cable. This is a good place to look for the minimum allowable bend radius. Flexible coax will hold its shape once bent to a certain extent. Flexible coax cable can not take the G forces that semi-rigid can and still hold its original shape. Nevertheless, flexible coax has its place in the market where cost of goods sold is often a concern.

Quite often long lengths of semi-rigid coax are loaded into a bender for processing. These long lengths are managed thru the bending cycle using what is called hitch feed. The initial straight lengths can be longer than the bender itself. However, with hitch feed built into the software, the bender can advance the coax with ease.

When bending semi rigid from a long stick, a cutoff saw is most often mounted onto the bender. After a specific configuration is bent, the cutoff saw mounted to the bender can be used to part the formed part from the long stick.

Quality Concerns When Fabricating Coax Cable

Being able to bend semi-rigid cable or flexible coax cable consistently can impact the VSWR to some extent. Within in the bend zone itself, additional surface defects such as dents on the outer jacket will influence the VSWR. Dents or defects in the straight sections between bends can also cause the VSWR to change. Dents or surface defects found in semi-rigid or flexible cable are often the result of manual labor oversights and are often attributable to of the following:

- Change in clamping pressure during the cutting and/or bending operation

- Manual handling variations during the cutting and/or bending operation

Summary

Cutting, stripping, and/or bending coax cable for industrial applications requires significant care during the fabrication process. A gentle touch coupled with consistent manufacturing processes can translate into quality coax cable assemblies destined for production.

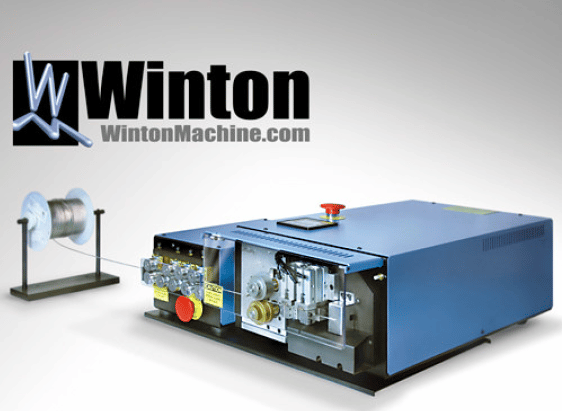

George Winton, P.E. designs and builds CNC tube fabrication equipment for Winton Machine in Suwanee, GA. He can be reached at gwinton@wintonmachine.com or 888.321.1499.

About the Machines We Build

All of our semi-rigid coax and tube fabrication machines at Winton are designed, manufactured, and tested in-house. We have a large line of standard products as well as the ability to engineer the best solution for our customer’s needs. Our experienced sales staff makes sure that our customers can justify their capital equipment investment by offering a solution that is exactly what they need in order to manufacture their parts. Please contact us today to discuss your project.