Extracting The Heat Within a Refrigeration System

How simple fabrication processes can jump start your heat transfer efficiency

Refrigeration systems are designed to transfer heat whereby the goal is to remove heat from a warm area and make the local environment cooler. You will find this process in household air conditioners, refrigeration systems, and anywhere where heat is not desired. Extracting this heat from a specific area depends, in part, on the ability of certain fabricated components to transfer the heat.

For example, a copper tube with a hot liquid flowing inside can dissipate the internal heat to the surrounding cooler air. This is accomplished to a large extend by the amount of surface area of the tube exposed to the surrounding air. Therefore, the amount of heat dissipation is, in part, dependent on the amount of surface area of the tube in contact with the surrounding air. Increase the surface area and up goes the amount of heat transferred.

One way to up the amount of heat transferred is to wrap a foil around the outside of the tube. This instantly increases the available surface area for the heat to dissipate. This idea is not new. Truth be told, the concept of wrapping a foil around a tube for the purpose of better heat transfer efficiency goes back to at least 1929. You might be surprised as to how may consumer products on the market today make use of some variation of a foil-wrapped tube.

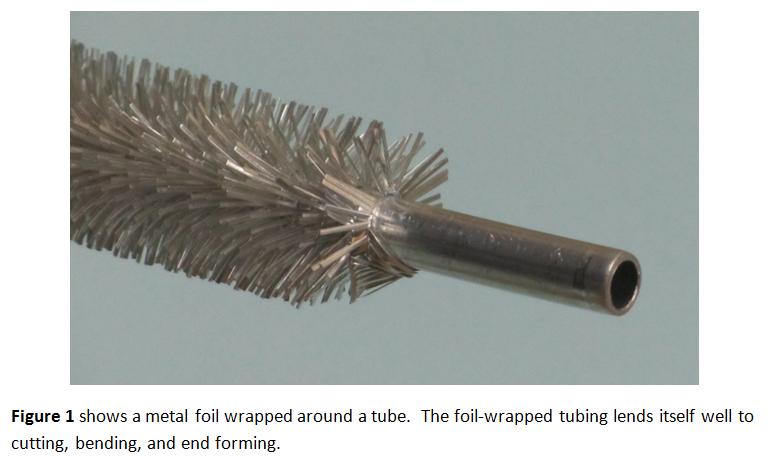

From Figure 1, a thin aluminum foil is wrapped around a metal tube. The foil itself draws the heat from within the tube. The surrounding air dissipates the heat thru convection. In short, the foil is able to dissipate more heat than the base tube alone because of the additional surface area of the foil in contact with the surrounding air.

Once the foil is wrapped around the tube, then is it time for cutting , bending, and end forming. Cutting the foil-wrapped tubing can be performed using one of several processes. One example can be seen in Figure 2.

The type of cut used in Figure 2 is a precision shear type cut. Once foil-wrapped tubing is cut, the tube’s ends can then be dressed in a secondary operation. A secondary operation might involve resizing the end of the tube so it can be connected to a larger system.

The foil wrapped tubing, also known as spine-fin tubing, has broad applications mostly involving evaporators and condensers primarily used to transfer heat. With a tube wrapped in foil, the ability for an evaporator or condenser to transfer heat becomes much more efficient.

George Winton, P.E. designs and builds CNC tube fabrication equipment for Winton Machine in Suwanee, GA. He can be reached at gwinton@wintonmachine.com or 888.321.1499.

About the Machines We Build

All of our semi-rigid coax and tube fabrication machines at Winton are designed, manufactured, and tested in-house. We have a large line of standard products as well as the ability to engineer the best solution for our customer’s needs. Our experienced sales staff makes sure that our customers can justify their capital equipment investment by offering a solution that is exactly what they need in order to manufacture their parts. Please contact us today to discuss your project.