Metro Atlanta, Georgia – Winton Machine was contacted by an HVAC equipment producer who manufactures commercial kitchen ventilation systems looking to increase accuracy and efficiency in their tube fabrication process. They specifically identified the need for a solution to eliminate a manual tube transfer to complete a secondary drilling operation.

Peter Reilly, Winton Machine Engineering Sales Rep, shared, “Once we learned more about their application and needs, we recommended using a CTL 30PA and a RD 30 eCNC. After a successful 3Q2017 installation and six months operating time to prove out the equipment, the customer ordered additional sets of the machines and tooling to be installed at other U.S. manufacturing facilities in 2018.” Reilly has been an engineering sales expert for Winton since 2004 and has been in the machine tool industry for 40 years specializing in tube bending solutions.

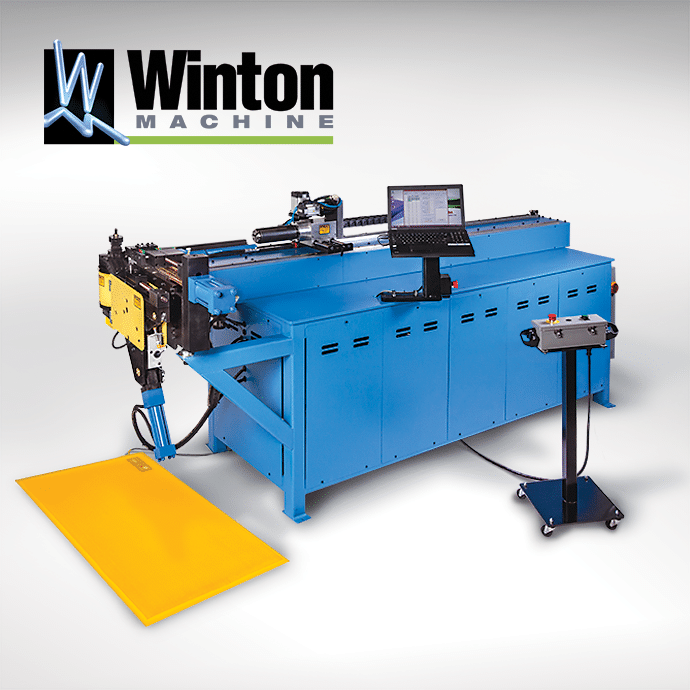

The Winton Model RD30 eCNC machines (pictured below) are designed to include an optional drilling feature that allows for holes to be drilled within the bending process eliminating the need for a secondary operation saving both time and cost. The CTL 30PA machines are designed to automatically feed and cut tubing with precision and speed. Batch programming as part of the Winton proprietary software ensures accuracy of the Winton CTL 30PA performance when tube lengths vary in one fabrication session.

“After being in the tube fabrication business for over 20 years, I’ve had many conversations with people who trust us to help them find a better way to produce their tube parts,” stated George Winton, P.E., President and Co-Owner of Winton Machine. “We keep in touch until an engineer, business owner or plant manager decides to take the next step – even if the cost justification or decision takes years. We often partner with customers to innovate on installed systems as needs change. This is how options like drilling and soft clamp become realities.” Winton is a Professional Engineer with over 30 years of experience designing industrial machinery.

Contact Winton Machine at 770-831-1917 or send an email to sales@wintonmachine.com to learn more about the RD30 eCNC and CTL 30PA.

About Winton Machine

Winton Machine manufactures over 100 different machines which use their proprietary software. Engineered solutions often become standard features on many of the machines. Winton has over 500 customers in the United States and in countries across Europe, South America and Asia.

Winton Machine proudly represented the State of Georgia at the 2018 Made in America Product Showcase held at the White House in Washington, D.C. Winton has been recognized by several state and local organizations for their contributions to Georgia’s manufacturing industry and their economic impact domestically and internationally.

Winton specializes in providing engineered solutions in major industries such as HVAC/Refrigeration, Aerospace, Automotive Aftermarket, Furniture, Electronics and Military. Winton is privileged to serve top companies and organizations in the U.S. and around the world. Learn more at www.wintonmachine.com.