Regripping a Short Pressure Die in Tube Fabrication

Being short on money typically isn’t good. Maybe you are thinking back on a life lesson you may have shared with your children on this very subject. On the other hand you may have experienced stopping short in an effort to avoid hitting the car in front of you. So going short can be a good thing.

So how does all this relate to tube bending? Well, when the magazine is empty, what do you do? You reload. When the gas in the tank is low, what do you do? You refill. Therefore, when the pressure die is too short, what do you do? You regrip! It’s that simple.

What Exactly is “Regripping”?

So what exactly is this regrip thing? Regrip is a software routine that can compensate for a short pressure die. You could always get a longer pressure die, but at the expense of a purchasing or cutting a longer pressure die. Maybe it is 5 o’clock on a Friday afternoon and you need to be bending at 7am on the next day. Now is the time to employ the regrip software routine.

For this discussion, the regrip process will be used in conjunction with a rotary draw bending machine. A typical serrano would be this: you have a pressure die that is just long enough to make a 90° bend. However, you have a bend in a part that is 110° and you don’t have a longer pressure die ready to go. You say to yourself “there is no way that this pressure die will make the 110° bend in one shot”. That is very true. So…take it in two shots!

How to Regrip Using a Short Pressure Die

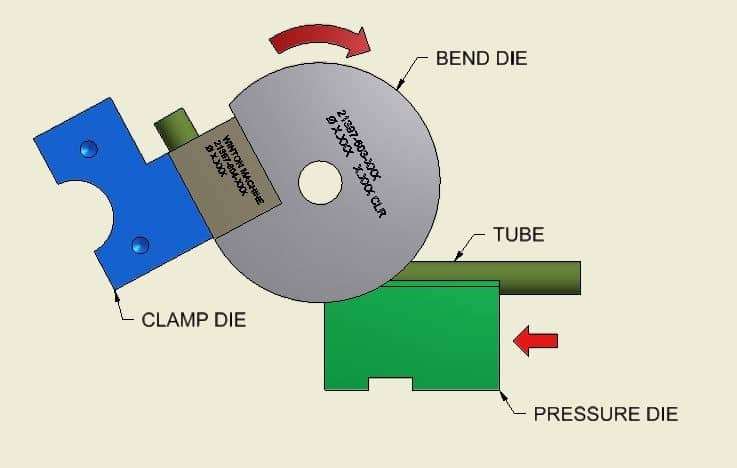

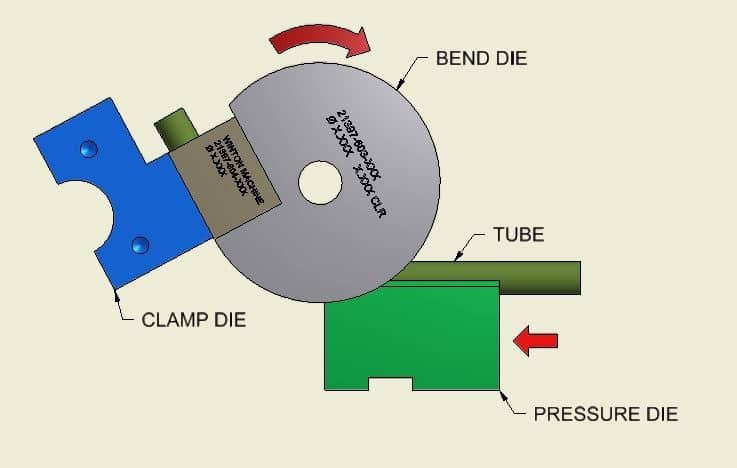

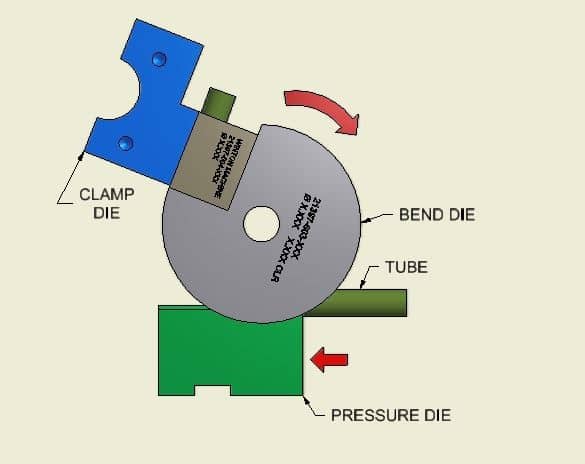

When regriping, a partial bend is first made; see Figures 1 thru 3 below. The bend head (swing arm) then pauses, the pressure die retracts in two directions, the pressure die then closes on the tube again (Figure 2), and the bend is completed (Figure 3). The regrip process itself all happens in under a second.

- Figure 1 above shows a partial bend (60°) formed. Notice that if the pressure die were to travel much further, it would fall off the tube.

Figure 2 above shows the pressure die after it regriped (repositioned) and before it advances out to complete the 110° bend.

Figure 3 above shows how the short pressure die was used to finish the 110° bend.

The benefit to this technique is that there is no need for a longer pressure die. With the regrip technique in the toolbox, more parts can be made with the same pressure die. This process can give tube fabricators a little extra flexibility when sizing up a job. You can regrip as many times as needed within one bend, the only limiting factor is the software that you are using. Finally, the regrip process is the opposite of the recapture process. Where regripping will compensate for a short pressure die, the recapture process can compensate for a pressure die that is too long.

George Winton, P.E. designs and builds CNC tube fabrication equipment for Winton Machine in Suwanee, GA. He can be reached at gwinton@wintonmachine.com or 888.321.1499.

About the Machines We Build

All of our semi-rigid coax and tube fabrication machines at Winton are designed, manufactured, and tested in-house. We have a large line of standard products as well as the ability to engineer the best solution for our customer’s needs. Our experienced sales staff makes sure that our customers can justify their capital equipment investment by offering a solution that is exactly what they need in order to manufacture their parts. Please contact us today to discuss your project.