Making Use Of The Right Hydraulic Power

Choosing the right type of hydraulic power supply can make all the difference.

The use of hydraulics to form tubing has been around for a long time. Well understood, hydraulics historically have been able to generate more power per dollar than an all electric equivalent. Yes, the inevitable hydraulic leaks never sit well with the maintenance folks. Nevertheless, in an age of going green, the simple fact remains that forming tubing via hydraulics continues to be an attractive economical choice. When choosing a hydraulic system, knowing the pros and cons of two common pump types can go a long way towards meeting a project’s objectives.

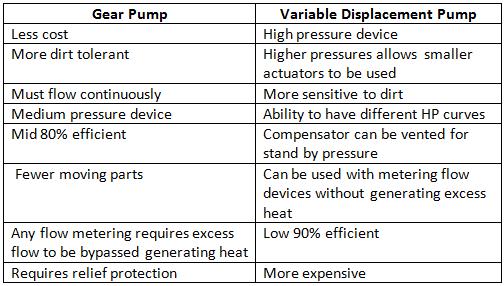

In the world of hydraulic tube fabrication machines, most systems make use of either a gear type pump or a variable displacement type pump. Although they both generate volume, they don’t always deliver the same type of performance.

Gear Pump

In its most simplistic case, a hydraulic power supply (HPS) that sports a gear pump is always trying to deliver a constant volume of fluid. This volume (flow) can be at a low pressure or at a high pressure; it depends on demand. Thus the pressure is a function of demand. If the system is running and is sitting idle, the system will maintain a lower pressure. When a directional control valve redirects (shifts) the flow to move a cylinder, the flow will try to remain constant while the pressure can rise sharply.

A HPS with a gear pump is good for sequential motion. Therefore, moving one cylinder at a time is a good application for a gear pump. Multiple cylinders can be moved simultaneously with a gear pump but it takes additional control valves to do so. Running a hydraulic tube bender from a gear pump doesn’t always produce the fastest cycle times.

Variable Displacement Pump

In contrast to a gear pump a variable displacement pump (VDP) delivers a constant pressure. The flow can be either low or high while sitting at a pre-set pressure. This works great when operating several hydraulic cylinders at the same time. As the demand for flow increases, the volume of hydraulic oil generated by a VDP increase as well. This is needed to supply the hydraulic cylinders…all at a pre-set pressure. It should be mentioned that there are a few different types of VDP. However, in general they all are designed to maintain a constant pressure.

Comparison Of The Two Different Types of Pumps

If you are purchasing a new fabrication system then chances are the type of hydraulic pump is pre-determined. However, if you are specifying a new fabrication cell/system, then a better understanding of hydraulic pumps may can come into play. Regardless if you are punching, end forming , or bending, knowledge of the different types of hydraulic systems can make all the difference in performance

George Winton, P.E. designs and builds CNC tube fabrication equipment for Winton Machine in Suwanee, GA. He can be reached at gwinton@wintonmachine.com or 888.321.1499.

About the Machines We Build

All of our semi-rigid coax and tube fabrication machines at Winton are designed, manufactured, and tested in-house. We have a large line of standard products as well as the ability to engineer the best solution for our customer’s needs. Our experienced sales staff makes sure that our customers can justify their capital equipment investment by offering a solution that is exactly what they need in order to manufacture their parts. Please contact us today to discuss your project.