Getting A Grip On Tube Bending

How a Collet Closer Can Influence Quality

A collet closer is found on a CNC or NC tube bender and serves an important role in the overall bending process. When quality is good, little attention is paid to its operation. However, when one or more quality features of a bent tubular product fall outside of acceptable limits, tracing the origin of the problem correctly back to the collet closer can often be initially overlooked.

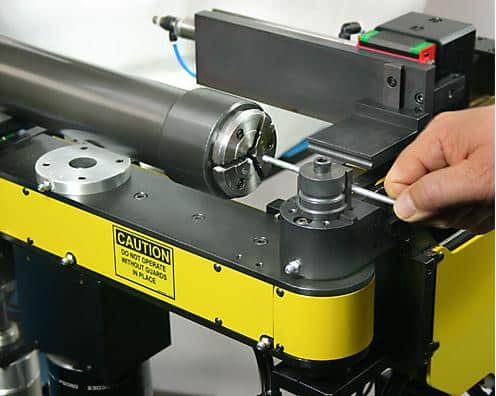

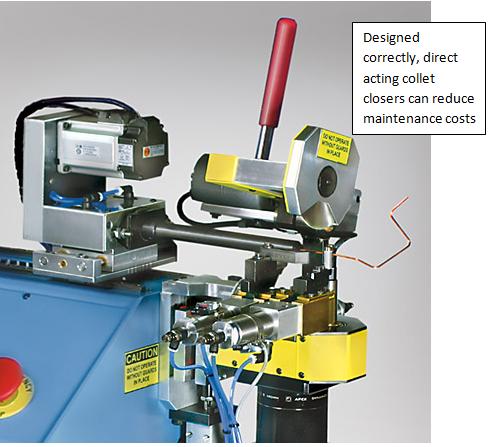

A collet closer on a CNC tube bender is a simple yet important device that must sing in harmony with the overall bending process. Having the collet closer open and close its grip repeatability on a tube at a precise point in time is often critical.

Collet closers come in various shapes on sizes. The vast majority of collet closers are powered by either compressed air (pneumatics) or hydraulics. All electric solutions are rare yet do exist.

Pneumatic solutions are often found on smaller CNC benders. Hydraulic powered solutions are more common where the forces produced by pneumatics are not sufficient to hold a tube. Nevertheless, when it comes to collet closers on a tube bender, what holds true for air often holds true for hydraulics.

Too Much Grip

Too much gripping force can turn the collet closer into a swaging machine; not good for quality. This is true for both hydraulic and pneumatic collet closers.

Too Little Grip

So what are some tell-tail signs of a light grip? In the case of a CNC tube bender where the carriage free floats in during the forming of a bend, too little grip can cause the tube to slip inside the collet pads. This often adds up to extra distance between bends.

If the carriage is intended to follow the bend head in (electronically geared) as the bend is being formed, a light grip (with no shoulder in the collet) can also cause the distance between bends to vary as the carriage attempts to press the collet pads over the tube axially. This often adds up to a shortage of distance between bends.

And then there is the plane rotation between bends. A light grip can cause slip between the collet pads and the tube thus causing the plane rotation between bends to vary outside of a specified tolerance. Sometimes a light grip on a tube can be compensated by adjusting the acceleration and/or deceleration time of the servo motor that controls the plane rotation. It is not the top speed of the plane rotations that causes the slip, it is the sudden starting /stopping that puts the most stress on the grip between the tube and the collet pads.

A good way to put most of these problems to rest is to make sure the bender’s software warns the user of a low pressure condition. Other root causes of a light grip might be:

- worn collet pads

- a mechanical malfunction of the closer itself

- an interment relay

- Sticking valve

- Lack of lubrication

- Incorrect collet pads installed

George Winton, P.E. designs and builds CNC tube fabrication equipment for Winton Machine in Suwanee, GA. He can be reached at gwinton@wintonmachine.com or 888.321.1499.

Related Documents

About the Machines We Build

All of our semi-rigid coax and tube fabrication machines at Winton are designed, manufactured, and tested in-house. We have a large line of standard products as well as the ability to engineer the best solution for our customer’s needs. Our experienced sales staff makes sure that our customers can justify their capital equipment investment by offering a solution that is exactly what they need in order to manufacture their parts. Please contact us today to discuss your project.