Coax Fabrication Machines

Machines to Cut, Bend, Strip, and Point Semi-Rigid Coax Cable

CNC Semi-Rigid Coax Benders

Our semi-rigid coax benders are designed to make precision bends in semi-rigid cable.

CNC Coax Cut-to-Length

Coax Hand Benders

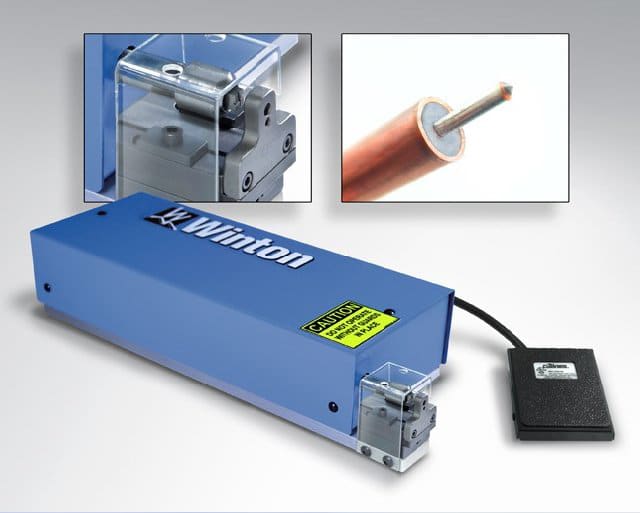

CNC Coax Stripper

Winton offers next generation semi-rigid coax stripper software. The new design features updated stripper heads allowing for more repeatable stripping of small diameter coax cable.

Coax Pointer Machine

Winton’s coax pointer machine is designed to use a high speed motor coupled with precision cutters to insure an accurate point on the end of a center conductor in one seamless motion.

Angle Measuring Machine

Contact Winton Machine

About the Machines We Build

Our factory automation solutions are used to help manufacture the NASA Mars Exploration Rover, Mars 2020, Raytheon Iron Dome Weapon System used to help protect over 8 million people in Israel to mass production of refrigerators built on General Electric assembly lines.

Winton Machine designs and manufacturers all our machinery onsite in Suwanee, Georgia – just northeast of Atlanta. We manufacture over 100 different machines and have also developed our own proprietary software that is used exclusively on Winton Machine products. The company continues to expand our core line of tube and coax fabrication equipment by adding customer-requested features and creating engineered solutions for the specific manufacturing needs of customers.